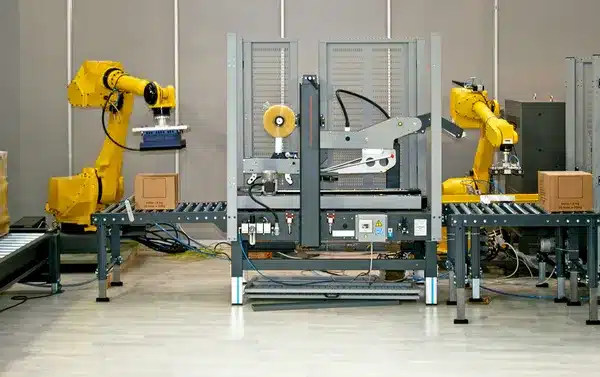

Packaging machines are vital for various industries, including food, beverages, pharmaceuticals, and consumer goods. As one of the world’s leading manufacturing hubs, China offers a wide range of packaging machinery at competitive prices, making it an attractive sourcing destination for businesses globally. However, the process of importing packaging machines requires careful planning, an understanding of logistics, and comprehensive knowledge of compliance and customs requirements.

This in-depth guide will walk you through the entire process of importing and shipping packaging machines from China—from choosing the right supplier and negotiating trade terms to handling shipping logistics, customs clearance, and beyond. We will also share best practices to ensure you have a successful experience, minimizing risks and ensuring a smooth operation for your business.

Table of Contents

Supplier Selection: Finding the Right Partner

Finding and Evaluating Suppliers

The success of your import process largely depends on choosing the right supplier. It is essential to do your due diligence and evaluate multiple potential suppliers before finalizing one. Here are some steps to help you get started:

Online Research: Use platforms such as Alibaba, Made-in-China, and Global Sources to find suppliers. These websites provide a wide selection of manufacturers, complete with reviews and ratings.

Supplier Verification: Ensure the supplier is verified and holds the necessary certifications like ISO 9001 for quality management. Look for suppliers with a proven track record of exporting to your target market.

Request Samples: To assess product quality, request samples or visit the supplier’s facility if possible. This will allow you to verify the manufacturing capabilities and quality standards.

Industry Expertise: Look for suppliers specializing in the type of packaging machinery you need, such as filling machines, wrapping machines, or cartoning machines.

Tonlexing Supplier Verification Services: At Tonlexing, we help businesses by verifying supplier credentials, ensuring that you work with trustworthy manufacturers that adhere to international standards. Our services also include factory audits and product quality assessments.

Communication and Establishing Trust

Clear communication is key when dealing with international suppliers. Here are some tips to establish a solid working relationship:

Frequent Communication: Regularly communicate via email, video calls, or messaging platforms to ensure clarity in requirements and timelines.

Contract Clarity: Draft a detailed sales contract that includes product specifications, delivery schedules, payment terms, and any other relevant conditions.

Due Diligence: Check for references and feedback from other clients. It is important to verify the supplier’s reliability, especially when making significant investments.

Tonlexing Supplier Liaison Services: Our team can help facilitate effective communication with your supplier, bridging language and cultural barriers to streamline the process.

Defining Product Specifications and Ensuring Compliance

Defining Product Specifications

Clearly defining the product specifications is crucial for importing packaging machines. Make sure to include the following details in your product specifications:

Machine Type: Specify the type of machine (e.g., filling, capping, labeling, or palletizing) that fits your business requirements.

Production Capacity: Define the production capacity you need in terms of units per hour or units per minute.

Material Compatibility: Confirm that the machine is compatible with the materials you need to pack, such as food items, pharmaceuticals, or cosmetics.

Voltage and Power Requirements: Ensure that the machine’s power supply specifications are compatible with your country’s voltage standards.

Compliance with Safety and Quality Standards

Packaging machines must meet safety and quality standards to be legally imported. Ensure the machines comply with regulations like:

CE Marking for the European Union: The CE mark certifies that the machine complies with EU safety, health, and environmental protection standards.

UL Certification for the USA: UL certification ensures that the machinery meets the relevant safety standards in the United States.

RoHS Compliance: For electronics, the machine may also need to comply with Restriction of Hazardous Substances (RoHS) to limit the use of hazardous materials.

Tonlexing Compliance Services: Tonlexing helps ensure that your packaging machines meet all necessary compliance requirements, including facilitating necessary certifications, to guarantee a smooth import process.

Negotiating Trade Terms and Placing an Order

Selecting Suitable Incoterms

Incoterms (International Commercial Terms) define the responsibilities of the buyer and seller regarding the shipment. Common Incoterms for importing packaging machines include:

FOB (Free on Board): The supplier delivers the goods to the port, and the buyer assumes responsibility for shipping.

CIF (Cost, Insurance, and Freight): The supplier pays for insurance and freight to the destination port.

DDP (Delivered Duty Paid): The seller is responsible for all transportation costs, including customs duties, until delivery to your facility.

Payment Methods and Financing

Choose a payment method that offers security for both parties. The following payment methods are commonly used:

Bank Transfer (T/T): Typically involves a deposit (e.g., 30%) upfront and the remainder before shipment.

Letter of Credit (L/C): A Letter of Credit is a more secure payment option for both buyers and suppliers and is ideal for larger transactions.

Escrow Services: For smaller orders, using escrow services may help protect both parties.

Tonlexing Trade Support: We help our clients negotiate favorable payment and shipping terms with their suppliers to secure the best possible conditions for their business.

Shipping Methods for Packaging Machines from China

Sea Freight

For bulky items like packaging machines, sea freight is the most common shipping option. You can choose between:

Full Container Load (FCL): If your order is large enough to fill an entire container (20ft or 40ft), FCL is a cost-effective and secure option.

Less than Container Load (LCL): Suitable for smaller orders that do not require an entire container. This option allows you to share container space with other shipments.

Advantages: Economical for large shipments and has a lower cost per unit. Disadvantages: Longer transit times compared to air freight.

Estimated Transit Time: 25 to 45 days, depending on the destination port.

Air Freight

Air freight is the fastest option and is suitable for smaller or urgently required machinery. While more expensive, it ensures quick delivery.

Advantages: Fast and ideal for urgent deliveries. Disadvantages: Higher costs compared to sea freight, particularly for heavy equipment.

Estimated Transit Time: 5 to 10 days.

Rail Freight for Europe

Rail freight is an excellent alternative for shipping from China to European destinations, offering a middle ground between air and sea freight.

Estimated Transit Time: 15 to 25 days.

Tonlexing Logistics Services: Tonlexing provides assistance in selecting the best shipping method based on your budget, timeline, and volume requirements. We handle FCL, LCL, air freight, and rail freight options to meet your needs.

How Much Does It Cost to Ship Packaging Machines from China?

The cost of shipping packaging machines from China depends on the mode of transport, destination, and shipment size. Below is an estimate for sea freight, air freight, rail freight, and express shipping:

Sea Freight (Cost-Effective for Large Shipments)

| Destination Port | 20ft Container (USD) | 40ft Container (USD) | LCL (Per CBM) (USD) |

|---|---|---|---|

| Los Angeles, USA | $2,800 – $3,500 | $4,500 – $5,500 | $120 – $150 |

| Rotterdam, Netherlands | $2,600 – $3,200 | $4,200 – $5,000 | $130 – $180 |

| Jebel Ali, UAE | $2,200 – $3,000 | $3,800 – $4,800 | $110 – $140 |

| Sydney, Australia | $2,700 – $3,500 | $4,500 – $5,500 | $140 – $180 |

| Durban, South Africa | $3,000 – $3,800 | $4,800 – $6,000 | $150 – $200 |

Air Freight (Fast and Reliable for Smaller Shipments)

| Departure Airport in China | Destination Airport | Estimated Cost (USD/kg) | Weight Range |

|---|---|---|---|

| Shanghai Pudong (PVG) | Los Angeles (LAX) | $4.5 – $6.0 | 100 – 300 kg |

| Guangzhou Baiyun (CAN) | Frankfurt (FRA) | $4.0 – $5.5 | 100 – 300 kg |

| Shenzhen Bao’an (SZX) | Dubai (DXB) | $3.8 – $5.0 | 100 – 300 kg |

| Beijing Capital (PEK) | Sydney (SYD) | $4.5 – $6.5 | 100 – 300 kg |

| Hong Kong International (HKG) | Durban (DUR) | $3.5 – $5.5 | 100 – 300 kg |

Rail Freight (For Europe Only)

| Departure Station in China | Arrival Station in Europe | 40ft Container (USD) | LCL (Per CBM) (USD) | Transit Time |

|---|---|---|---|---|

| Xi’an | Hamburg, Germany | $7,000 – $8,500 | $250 – $300 | 18-25 days |

| Chengdu | Warsaw, Poland | $6,800 – $8,200 | $240 – $280 | 20-27 days |

| Chongqing | Milan, Italy | $7,200 – $8,800 | $260 – $310 | 18-25 days |

Cost-Saving Tips

- Consolidate Shipments: Combine smaller shipments to maximize cost efficiency.

- Choose Sea Freight for Large Machines: FCL or LCL options are ideal for bulkier packaging machines.

- Book Early: Reserve space in advance to secure better rates, especially during peak seasons.

- Optimize Packaging: Reduce volumetric weight for air freight by using efficient packaging methods.

Customs Clearance: Requirements and Documentation

Required Documentation

To successfully clear customs, it is necessary to have all the required documents prepared accurately. Typical documents include:

Commercial Invoice: Details the value and nature of the goods.

Packing List: Lists all the contents, dimensions, and weights of the packages.

Bill of Lading or Airway Bill: Proof of shipment.

Certificate of Origin: Certifies the origin of the goods, which may impact the duty rates.

Duties and Taxes

Import duties and taxes are calculated based on the HS Code for the packaging machines. It’s essential to verify these costs with local customs authorities to avoid unexpected charges.

Tonlexing Customs Brokerage: Tonlexing’s customs brokers manage all aspects of customs clearance, ensuring compliance with local regulations and preventing unnecessary delays or penalties.

Packaging and Handling for Shipping

Proper Packaging for Machinery

Packaging machines need to be packed securely to withstand long transit times. The following are key packaging considerations:

Wooden Crates: To provide protection from impacts during transit.

Foam Padding: To absorb shocks during handling and transport.

Moisture Protection: Use plastic wraps and desiccants to protect machines from moisture and corrosion.

Handling Large Equipment

Packaging machines can be large and heavy, requiring specialized handling equipment such as forklifts or cranes during loading and unloading. Coordinate with your shipping provider to ensure all necessary arrangements are made.

Tonlexing Packaging Services: Tonlexing provides comprehensive packaging solutions, ensuring your machinery is safely packed to prevent any damage during transit.

Best Practices for Importing Packaging Machines

Quality Assurance and Inspection

Packaging machines need to be packed securely to withstand long transit times. The following are key packaging considerations:

Wooden Crates: To provide protection from impacts during transit.

Foam Padding: To absorb shocks during handling and transport.

Moisture Protection: Use plastic wraps and desiccants to protect machines from moisture and corrosion.

Clear Communication

Maintain clear communication with your supplier about product specifications, delivery timelines, and any changes to your requirements to ensure a smooth process.

Partner with a Reliable Freight Forwarder

A professional freight forwarder like Tonlexing can help manage logistics, documentation, and customs clearance, ensuring that your goods are delivered efficiently.

Tonlexing End-to-End Support: Tonlexing provides a complete solution, from sourcing suppliers to customs clearance and final delivery, making the importing process as seamless as possible.

Tonlexing's Comprehensive Import Services

1. End-to-End Solutions

Tonlexing offers complete end-to-end import solutions, including supplier verification, logistics management, documentation, customs clearance, and delivery.

2. Cost Optimization

We work closely with leading shipping lines to offer competitive freight rates. Our experts help you optimize shipping costs, whether it’s sea, air, or rail freight.

3. Customs Compliance

Our customs experts handle all documentation, customs duties, and compliance issues, ensuring that your imports meet local regulations.

4. Real-Time Tracking

Tonlexing provides real-time tracking so you know the status of your shipment at every stage. Our dedicated support team is available to answer any questions.

Contact Tonlexing Today: Let Tonlexing simplify your import process for packaging machines. Reach out to us today for tailored shipping solutions and professional support.

Importing and shipping packaging machines from China can be a cost-effective way to enhance your production capabilities. With the right planning, supplier selection, logistics, and compliance, the process can be smooth and efficient. Working with an experienced logistics partner like Tonlexing helps streamline each step of the process, minimizing risks and ensuring that your machinery arrives safely and on time.

Tonlexing is committed to being your partner in success, providing customized import solutions to meet your business needs. Whether you are importing your first machine or expanding your production capacity, we are here to help. Contact us today to learn more about our services and get started on your importing journey.